KANBAN

A Kanban is a communication signal used to initiate work in a process.

The Kanban is typically used as a tool in a pull system that attempts to reduce overproduction waste by responding to customer orders as opposed to forecasting customer demand.

A Pull System uses the orders of the customer to signal production upstream.

This structure is used in the Just-in-time method of production to reduce the levels of inventory and shorten the lead time in delivering a product to the customer.

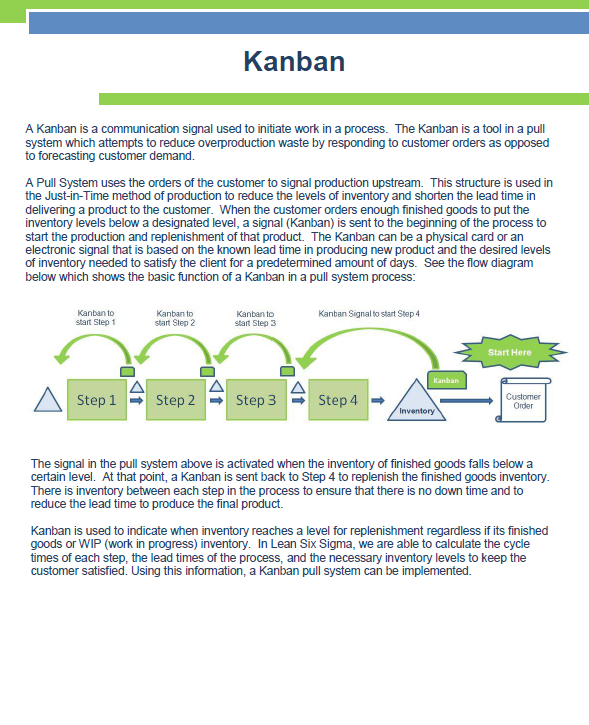

When the customer orders enough finished goods to put the inventory levels below the designated level, a signal (kanban) is sent to the beginning of the process to start the production replenishment of that product.

The Kanban can be a physical card or an electronic signal that is based on the known lead time in producing new products and the desired levels of inventory needed to satisfy the client for a predetermined amount of days.

The signal in the pull system above is activated when the inventory of finished goods falls below a certain level. At that point, a Kanban is sent back to Step 4 to replenish the finished goods inventory.

There is inventory between each step in the process to ensure that there is no downtime and to reduce the lead time to produce the product.

Kanban is used to indicated when inventory reaches a level for replenishment regardless of its finished goods or WIP (work in progress) inventory.

In Lean Six Sigma, we are able to calculate the cycle times of each step, the lead times of the process, and the necessary inventory levels to keep the customer satisfied.

Using this information, a Kanban pull system can be implemented.