Lean Six sigma Certification

Take your project management skills to the next level with a Certification in lean six sigma.

Companies that use our training ...

Get Certified Today

improve productivity & results. A “Belt” signifies experience. Practitioners are given a “Belt”

title (Black Belt, Green Belt, Yellow Belt) that corresponds to their level of experience.

We Offer Lean Six Sigma Certification Prep Training

For Individuals and Corporate Teams. Online (Self-Paced); Online (Instructor-Led);

In-Person (Public Groups/On-Site) and Private 1:1 sessions.

Black Belt

Certification

Expert knowledge & skills related to the DMAIC methodology, & team leadership.

Green Belt

Certification

Yellow Belt

Certification

Practice

Exams

Personalized

Mentorship

Program 2023

- Flexible self-paced training that is designed to work for everyone

- Structured schedule that keeps the entire team on track

- Live online group sessions that creates an immersive learning experience where team members learn from each other’s experience and work deliverables.

- Practical approach that encourages trying, coaching and correction to enhances skill building and application of concepts to real life projects.

- Customizable to ensure our approach fits your needs and achieves your goals.

Consulting

Experts For

Transforming your organization

Let us help you realize your process improvement goals.

We have a team of consultants with over 40 years of combined Lean Six Sigma consulting and deployment experience.

Contact us today to be matched with a certified MBB that will fit your needs, budget and your organization.

Personalized

Lean Six Sigma Mentorship

Program 2023

- Flexible self-paced training that is designed to work for everyone

- Structured schedule that keeps the entire team on track

- Live online group sessions that creates an immersive learning experience where team members learn from each other’s experience and work deliverables.

- Practical approach that encourages trying, coaching and correction to enhances skill building and application of concepts to real life projects.

- Customizable to ensure our approach fits your needs and achieves your goals.

Consulting

Experts For

Transforming your organization

We have a team of consultants with over 40 yers of combined Lean Six Sigma consulting and deployment experience.

Contact us today to be matched with a successful Certified Master Black Belt that will fit your needs, your budget and your organization.

Why Use

MySixSigmaTrainer?

We help business professionals gain critical problem-solving skills, get more credibility & stand out with their employers so they can get bigger roles and higher salaries without working harder.

Over the course of a few short weeks, we work closely with them to transform their resumes and their careers.

We do this by helping them learn and apply the principles of the Lean Six Sigma framework of problem-solving and project management.

They learn how to apply each step of the Six Sigma 5-phase DMAIC methodology to everyday business problems.

This helps them create value and improve their employers’ bottom-line by removing waste and standardizing their business processes so they can increase revenues or cut costs/expenses.

Our clients include corporate teams from small to fortune 500 companies … project managers, business analysts, business process managers, industrial engineers, warehouse managers, operations managers, IT managers, HR managers or most job-seeking professionals.

Our training is relevant to any industry whether it be manufacturing, services, financial services, consulting, construction, healthcare, etc. They learn how to apply Six Sigma to any business process, removing waste, and reducing variation.

The Six Sigma data-driven methodology helps to create value for employers by:

Reducing Cycle Time

Increasing Productivity

Reducing process steps

Creating happy, loyal customers

Standardizing business processes

Simplifying processes and workflow steps

Decreasing maintenance and support costs

Increasing profitability of existing products/services

And More

Our students love our program because we don’t just give them a certification/badge, we teach them how to use Six Sigma successfully. We teach them essential soft skills (eg. communication skills, working with teams, influencing, facilitation skills, and more) plus we help them find work.

Jennifer Holbus, Founder & Owner

IASSC Accredited Curriculum Provider

Benefits

A Lean Six Sigma Certification can skyrocket your career

- Become a change agent within your organization.

- Leading efforts to improve processes and the quality of what is delivered to customers.

- Better job opportunities and improved salary.

- Six Sigma training prepares students for a leadership role.

- New career possibilities with higher salary potentials.

- Improve your business acumen, analytical skills and your commitment to improving the business within which you work.

- Six Sigma certifications demand so much respect is that they are not easy to attain, and executives and hiring managers at major companies know this.

- Reduce costs, increase revenue, streamline business

Benefits

A Lean Six Sigma Certification can skyrocket your career

- Become a change agent within your organization.

- Leading efforts to improve processes and the quality of what is delivered to customers.

- Better job opportunities and improved salary.

- Six Sigma training prepares students for a leadership role.

- New career possibilities with higher salary potentials.

- Improve your business acumen, analytical skills and your commitment to improving the business within which you work.

- Six Sigma certifications demand so much respect is that they are not easy to attain, and executives and hiring managers at major companies know this.

- Reduce costs, increase revenue, streamline business

New to Lean Six Sigma?

Lean and Six Sigma tools.

LEAN FUNDAMENTALS

A set of tools developed to reduce the waste associated with the flow of materials and information.

SIX SIGMA FUNDAMENTALS

Focus on helping you reduce variation in processes, streamline production, improve quality and gain customer loyalty.

What is Six Sigma?

and maximizing business success.

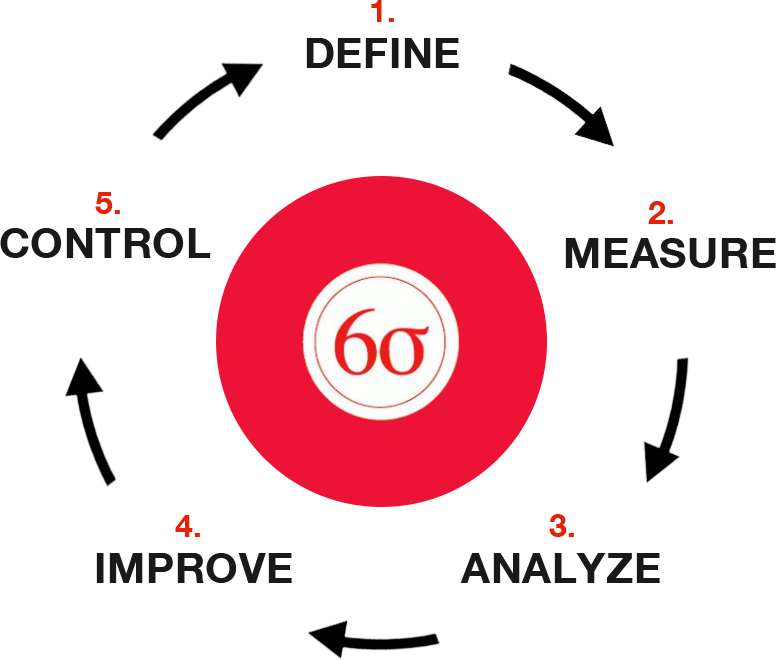

Define, Measure, Analyze, Improve, Control.

* Refer to the graphic below

and techniques that guide the problem

solver through the improvement process

from start to finish.

What is “Lean”?

Lean (also referred to as Lean Methods or Lean Speed) is a set of tools developed to reduce the waste associated with the flow of materials and information in a process from beginning to end. The goal of Lean is to identify and eliminate non-essential and non-value added steps in the business process in order to streamline production, improve quality and gain customer loyalty.

Lean Methods can be employed within the DMAIC framework to augment Six Sigma tools when the project focus is to improve process speed and efficiency.

How Did it Become “Lean Six Sigma?”

Using more problem-solving techniques can help solve a larger number and variety of business problems. Starting in the 1980’s, consultants trained in both techniques realized the synergy between Lean and Six Sigma and began to push for the combination of the different tools of Six Sigma (focused on improving quality) and Lean (focused on removing waste).

Thus, Lean Six Sigma (LSS) was born.

Client Feedback

The programs offered by MySixSigmaTrainer and services they offer make it easy to form a lasting relationship with everything you need in one place. You will be in good hands with Jennifer and MySixSigmaTrainer.

A big thank you, to Jennifer. I will forever be an advocate of you and your team.

Get Started

Take A Course!

Select from one of our different

level Lean Six Sigma

courses.

Become an Instructor

Join our growing team of instructors dedicated

to success.