PROCESS CYCLE EFFICIENCY

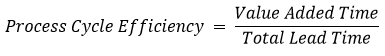

A useful calculation in prioritizing improvement opportunities in a process is the Process Cycle Efficiency. The Process Cycle Efficiency is calculated by dividing the value added time of a process by the total lead time of a process:

Value added time is the portion of processing time that changes the product in a way that is valuable to the customer (Conversely, time spent on activities that do not change the product in a way that is valued by the customer is considered waste). For example, if a process exists to roast coffee beans the time spent heating and rotating the beans is value added time because the beans are being changed in a way that the customer requires. On the contrary, the time spent calibrating the ovens for roasting is not value added time, although it is a necessary step.